|

|

|

This is only a sample

mount for the LED. This is not necessary. I just wanted to. I

figure I may be moving this system to another heli in

the future. So to make things easier put the work

in now. |

|

| |

|

|

|

|

Carbon fiber material

was cut

to the size of the LED. Use fuel tubing and rubber

washers. An L-bracket is used for mounting. |

|

| |

|

|

|

|

Mounted the LED

underneath the adapter plate.

Notice the

double-sided tape underneath the plate. This is to

prevent movement. Small strips is all that is

required. |

|

| |

|

|

|

|

During the review the

wire

must have bent back and forth to cause the

soldering point to break.. |

|

| |

|

|

|

|

Unsoldered the

wires. Re-strip, cleaned and re-soldered. New heat

shrinks were also used. |

|

| |

|

|

|

|

To prevent this from

happening again "Shoe Goo®" was used to protect the wires. |

|

| |

|

|

|

|

Then used a clear

heat shrink to further protect the wires. The heat

shrink also protects the soldering points from shorting

them accidentally. |

|

| |

|

|

|

|

Cut holes for the LED

and reassembled with the carbon fiber plate.. |

|

| |

|

|

|

|

This assembly is much

more solid. |

|

| |

|

|

|

|

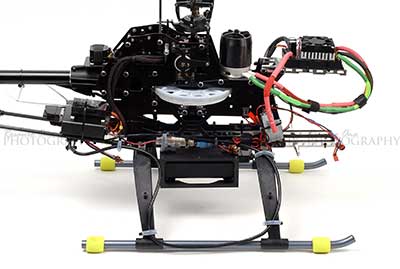

Mounted the LED in

the same place as previous. |

|

| |

|

|

|

|

A closer look at the

L-bracket mounting. |

|

| |

|

|

|

|

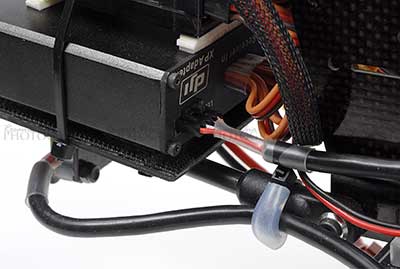

Plug the LED wire

into the LED port on the adapter.

Notice wire

protection on the LED wire. |

|

| |

|

|

|

|

| |

|

| |

|

| |

|

|

UPDATE

- LED Replacement - May 14, 2009 |

|

| |

|

|

|

|

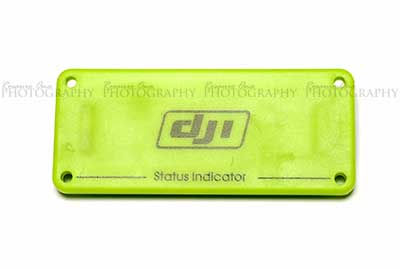

As promised, DJI sent

me a replacement LED.

No more exposed

solder connections. The LEDs are now sealed.

Its dimensions are

80mm x 34mm. |

|

| |

|

|

|

Solid back.

Safe to use Velcro or double-sided tape. |

|

| |

|

|

|

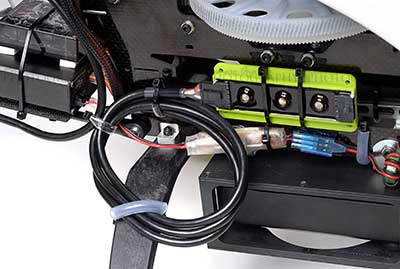

Cable can now be

separated. |

|

| |

|

|

|

Either end of the LED

can be used to plug the cable into. |

|

| |

|

|

|

Cable has two

different connectors. The connector to the left

plugs into the LED. |

|

| |

|

|

|

Mounted the LED on

the side using Velcro and tie-wraps. |

|

| |

|